How to Have Visibility Between Management and Manufacturing/Production

Do you find yourself wondering how to have visibility between management and manufacturing in your company? Being able to access and analyze up-to-date data is essential to the future success of your business. Unfortunately, many manufacturers lag in collecting and using data that can help them improve their production operations and processes. The key is to embrace new technologies that provide improved data visibility throughout the organization and then make the best use of that data and its insights. Read on to learn more.

Why Data Visibility is Critical for Manufacturing/Production

Data collection, use, and visibility are essential for managing day-to-day manufacturing operations and generating informed production and inventory forecasts. Improved data visibility can provide several significant benefits for any manufacturing company.

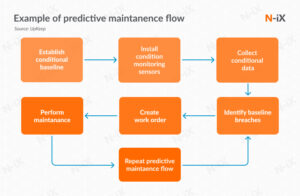

Reduced Downtime

Increasing management visibility into critical usage data can predict necessary maintenance, avoid equipment breakdowns, and reduce production downtime. It’s all about using the data generated by machines and their operators to perform predictive maintenance. Making this data visible to management is key to providing more effective maintenance schedules.

More Accurate Production Forecasting

Being able to predict demand is key to efficient production. Ensuring management visibility to both current and historical data improves demand forecasting, enabling more accurate production forecasting. Being able to more accurately plan labor needs, equipment usage, and raw materials availability leads to a significantly more efficient manufacturing operation.

Fewer Supply Chain Disruptions

The COVID-19 pandemic has resulted in supply chain disruptions unlike any others in recent memory. Better access to big data enables manufacturers to anticipate supply chain issues more quickly and make alternative plans to avoid disruptions in their production operations.

Improved Quality Control

The data generated by manufacturing equipment and processes can help identify quality issues as they develop, not days or months later – but only if that data is made visible to appropriate management. Quickly detecting potential defects enables the affected product to be isolated and the issues corrected before entire runs are impacted.

Better Decision Making

Data visibility results in data sharing – and data sharing results in better decision making. Critical information and knowledge are more easily passed from the manufacturing floor to the management suite, enabling more informed decision-making.

Manufacturers Lag on Data Usage and Visibility

Unfortunately, the manufacturing industry suffers from a disconnect between data collection and its use. Seagate’s Rethink Data report notes that the manufacturing sector has the lowest level of data automation – only 9% of manufacturers fully integrate their data management functions on a single platform. The industry also lags in adopting cloud-based technology, with most manufacturers still basing their data operations in traditional on-premises data centers.

As a result, many manufacturers have difficulty connecting to their assets on the factory floor. According to a survey by Magic Software, almost half (42%) of manufacturers have little or no visibility into the production process. Instead, they end up “guesstimating” material and production costs, with less than acceptable results.

What is causing this lag in data usage in the manufacturing sector? There are several factors, including:

- Continuing reliance on legacy infrastructure and systems

- Data silos isolating essential data within different departments

- Difficulty in extracting data from different equipment and processes

- IT skills gap compared to other industries

How to Have Visibility Between Management and Manufacturing

To improve data visibility in your organization, you must embrace change. That means moving beyond legacy infrastructure and modernizing systems and operations – all in service of making your valuable data more visible and actionable across the entire company.

Modernize Legacy Systems

Legacy systems and processes are holding you back. Outdated systems make it difficult to adopt new technologies and affect significant change. You need to push key stakeholders to let go of their old ways to move forward with 21st-century solutions and replace those legacy systems with more modern solutions, including enterprise resource planning (ERP) and customer relationship management (CRM) platforms.

Eliminate Data Silos

Legacy infrastructure typically stores data in departmental silos. Production stores its data separately, as do sales, marketing, and even your warehouse. To make data visible across your entire organization, you need to tear down these data silos and consolidate all of your data into a single unified data repository that all departments and individuals can access equally.

It also means sifting through the collected data to weed out outdated, incomplete, and just plain bad data to create a “clean” database to serve as what Salesforce calls “a single source of truth” for all your employees.

Move to Centralized Cloud Storage

Your new centralized data repository needs to be accessible by employees across your entire organization, no matter what department they’re in or where they’re physically located. This argues for storing your company’s data in the cloud, where any authorized user can access it from any device connected to the Internet. This frees your data from legacy on-premises servers’ constraints, which should improve data management and security while reducing costs.

Upgrade IT Staff

Hand-in-hand with upgrading legacy systems and equipment is upgrading your IT staff. You need an IT department well-versed in modern systems and technologies that can move your business forward in terms of data usage and visibility.

Utilize Third-Party Services

Finally, consider employing third-party services, such as Rainmaker, with experience in both technology and manufacturing. Rainmaker has worked extensively with numerous manufacturing companies and knows what technologies and solutions are the best choices for improving data visibility and ensuring more efficient manufacturing operations.

Let Rainmaker Help You Improve Visibility in Your Manufacturing Operation

When you want to improve data visibility between management and manufacturing, turn to the manufacturing experts at Rainmaker. We offer a variety of Salesforce-enabled services to ensure that your management, manufacturing, sales, marketing, and other functions are all working together to achieve your company’s shared goals.

Our expert staff can help you integrate key systems and processes, including ERP and customer care systems, to share and make visible all the valuable data you collect. We also offer a wide variety of Salesforce Managed Services to help your company grow sales, improve customer service, and make your business more profitable.

Contact Rainmaker today to learn more about improving data visibility in manufacturing operations!